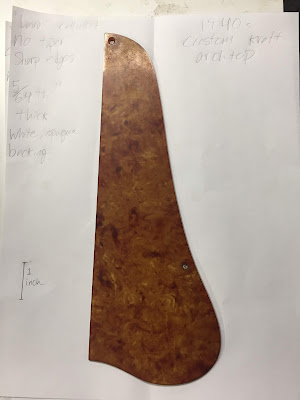

The worst guitar I have seen to date

I am confident that this guitar was left in the heat somewhere, whether in a vehicle or a house, and has since warped itself apart. I have never encountered soundhole warping to the degree that this guitar has nor do I think it could have occurred naturally form string tension. I don't have a lot of money into this guitar so I can try techniques that I have never attempted before.

|

| Wooden nut, Art Deco-styled logo |

Diving In

First thing I noticed is that the back was separating from the rest of the guitar and so that made attempting to take it off quite easy. I followed the advice I saw on Stewmac and built a cardboard support to help the body hold its shape while the back was off.

The second thing I noticed was the faint smell I encountered previously had developed into a full blown stench in the presence of heat and water. This guitar smells nasty. Its hard to explain but I had to work on it outside for fresh air and the reddish glue I think is the cause of the odor. I'm working on it in pieces and in the mean time the rest of the guitar is sitting in an isolated closet with a dish of baking soda in hopes of removing the scent. I tried Febreeze (the cornstarch-based mixture, not the aerosol) and Pet Urine Remover (my first thought) but it still lingers behind.

The back came off quite easily, I used a putty knife that I kept in a container of very hot water to slide around the edges and pry it off. Luckily this guitar is only bound on the top so I did not have to mess with any binding and the paint is so damaged from the heat that I doubt anyone will notice that the back came off.

It was super fascinating to dive into this guitar as you see pencil marks and stamps and other clues left behind by the craftsmen who built this guitar so long ago. The history behind these instruments is one of my favorite parts of working on old guitars. I initially figured that these guitars were plywood but they are indeed solid wood, not sure what kind but the top, back, and sides are made of the same wood and it isn't spruce.

The guitar's back has two almost-parallel warped spots that go length-wide near where the neck meets the body. Those braces are holding on by a prayer a la Bon Jovi

|

| The piece of tape in the upper right is holding on a cleat |

I used an acid brush (disposable and cheap) dipped in my container of hot water to loosen the glue and then my putty knife and chisel to clean up the areas. I decided to brush the water around the corners of all the braces to soften the old hide glue and then I painted on some new, fresh fish glue to really help cement the braces in place.

I quickly realized that I don't have enough deep clamps to tackle all of clamping that needed to get done so I'll probably do it in segments next time but this works for now. The upper-most brace needed to come off entirely and then I wet the wood with hot water and let it sit between two blocks of wood before attempting to force it around the brace again. I've never messed with the tops or backs of guitars like this before so I know there should be a slight radius (flat top is a bit of a misnomer) and I'm hoping the braces will force that radius back into the body.

Regluing the back

As of 6/24 I have the back reglued and just pulled the neck off in order to do a neck reset. Regluing the back onto a guitar is trickier than I thought since the sides of the guitar often want to "dive" or "lean" certain directions which differ from where they were when the guitar was first built.. I also should have invested in spool clamps or at least more clamps to make sure the body was adhered evenly. I'll get back to fixing that soon enough.

The neck came off fairly easily and I got to work on resetting the neck. In the process I managed to break off the fretboard extension which leads me to continue to curse "fruit wood" and "ebonized" fretboards as they are extremely delicate and difficult to keep from fracturing. I'll put it back together and it should be fine.

Dating

The art deco logo would put this guitar around the 1940s and early 50s but I wanted to know for sure so I went through and wrote down the contents of all the stamps within the guitar. I did not get pictures of them and unfortunately the process of steaming the guitar back together has mostly destroyed the ink and therefore the stamps.

The guitar was stamped, approximately as the ink was already faded, 8869H614 on the top just above the first brace. On the back it was stamped F-54 as well as some unreadable characters and then below it I could just barely make out "Made in U.S.A" and that was entirely enclosed in a box the same color as the text.

|

| Recreation of the date label stamped on the back of the guitar |

H614 should be the model number of the guitar built by Harmony but information is sparse and so I can only assume there is a similar model under the Harmony name out there. 8869 is apparently a mostly meaningless number, likely referring to each specific guitar within a batch but I have no proof of it.

F-54 means that this guitar was built in 1954 and the F either stands for "Fall" or "First half of the year" depending on who you ask. The one constant is that this guitar is from the 1950s like I previously suspected.

.png)

No comments: